When it comes to claims and disputes, I have often heard the proverbial advice that “you should document everything.” However, in reality this is rarely done and it is often impossible to accomplish. Normally, the folks on a construction project simply don’t have the time to write down everything that’s going on at the site and at every project meeting and then respond to every email and phone call. In fact, I would not advise you to try! Doing so would be frustrating at best and counterproductive at worst. Your management team should be focused on managing the project. This is especially true on a troubled project, where you have to put out one fire after another. Your team’s efforts should be focused on using their time in the office wisely and making sure that the important items are properly documented. So, how are they supposed to know which of the items are the most important to document? This article attempts to answer that question by establishing some rules and by providing an objective framework that can be used when deciding how and what to document.

When it comes to claims and disputes, I have often heard the proverbial advice that “you should document everything.” However, in reality this is rarely done and it is often impossible to accomplish. Normally, the folks on a construction project simply don’t have the time to write down everything that’s going on at the site and at every project meeting and then respond to every email and phone call. In fact, I would not advise you to try! Doing so would be frustrating at best and counterproductive at worst. Your management team should be focused on managing the project. This is especially true on a troubled project, where you have to put out one fire after another. Your team’s efforts should be focused on using their time in the office wisely and making sure that the important items are properly documented. So, how are they supposed to know which of the items are the most important to document? This article attempts to answer that question by establishing some rules and by providing an objective framework that can be used when deciding how and what to document.

1. SUPPORT YOUR POSITION

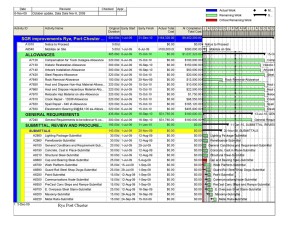

Spend the time to write the letters or emails that support your position and explain why your position is correct. This should be the overall framework from which you are focusing your documentation efforts. Document the issues and events as they occur; take a photo, write an email, or put an extra note in the daily report that explains the event or occurrence from your perspective. Pay particular attention to items that delay or disrupt the critical path work on the project, such as: design errors and omissions, missing information (such as unanswered RFI’s), differing site conditions, changes that disrupt the critical work, critical path delays (inability to start or finish work in the critical areas of the project), loss of productivity (interference or additional mobilizations to complete work in the critical areas) and acceleration (working overtime to make up lost time or compression of work or stacking of trades in a schedule). In general your documentation efforts should be focused on those things occurring on the project that results in a growth of cost and that could not have been anticipated at the time of bid. Make sure there is evidence in the file that supports and explains your position as to why the growth in cost occurred. Connect the dots between the event or issue and the actual growth in cost. You’d be surprised how the resolution of an issue was won or lost based on the existence or absence of a crucial piece of documentation in the file.

2. RESPOND TO EVERY LETTER

When is it necessary to write a letter? When someone writes one to you. It is not necessary to engage in a letter-writing campaign (it is simply not true that the person with the highest stack of letters automatically “wins”). But, for each letter that’s written to you make sure there is a written response in the file. One solid letter for each issue is a good rule of thumb. Get your points documented, keeping in mind tip #1, above.

3. BE PROFESSIONAL

In your written correspondence, always be professional and stick to the facts. Be objective, rational and unemotional. There is no need to tell the owner’s rep that he’s an idiot (even if he is). Many people may be involved in the resolution of the dispute after the project is over and they may never meet you. People are going to form their opinions of you based on what you say and how you say it.

4. GIVE NOTICE

Notice provisions are written into contracts for a reason. Their purpose is to give the other party time to investigate, mitigate expenses, and track costs. Read your contract and make sure you are complying with the notice requirements. To make giving notice easier, we recommend that our clients develop form notices. At a minimum, we suggest having form notices available for each of the following situations: (a) Excusable Delay / Request for Time Extension, (b) Differing Site Condition, (c) Conflicting Specifications, (d) Acceleration (Directed or Constructive), (e) Disruption of Work Force, and (f) A/E Change. Have your lawyer review the notices before using them in the field.

5. RESERVE YOUR RIGHTS

I have been involved in several lawsuits in which the judge upheld signed releases on payment applications and change orders, and barred recovery for delay / disruption damages. Have your lawyer review the release language on any document before you sign it. At a minimum, cross out the offending language, or simply write that you are reserving your right to additional money or time for the impact encountered on the project or as a result of the change.

Knowing how and what to document will keep your team focused on managing the project and put your company in a much better position when it comes to resolving disputes when they arise.