While the more traditional project plan of design-bid-build is still popular in North Carolina, lately there has a sharp increase in the demand for alternate project delivery methods l. These alternative project delivery methods include:

- Design-Build

- Integrated Project Delivery (IPD)

- Public-Private Partnerships (P3)

- Construction Manager at Risk (CM-at-Risk)

More and more owners are seeking these alternative methods because they offer greater efficiencies and less risk in the construction process. Even state government agencies have begun using more alternate project delivery methods, especially design-build and CM-at-Risk.

The maturation of new delivery technologies is also increasing demand for alternative project delivery methods. Some such technologies include:

- Building Information Modeling (BIM)

- Virtual Design and Construction (VDC)

- Lean Planning

- 4-D Scheduling

These technologies work best in collaborative settings, where all parties involved in the construction process have input from the start of the project. Owners who are looking for this type of setup will search for a team that has previous experience with these technologies and team organizations.

From 2009-2011, North Carolina experienced a significant decrease in the amount of design-build projects, as the decline in the economy gave owners a strong incentive to save money by using the more traditional hard-bid design-bid-build project method. But over the last six months we have seen a dramatic resurgence in alternate project delivery proposals and more qualifications-based selections. Price is no longer the deciding factor in many projects in North Carolina and owners are free to choose the most qualified teams for their specific needs.

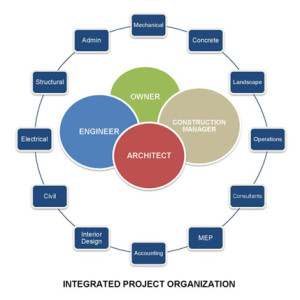

In the future, we expect to see an increase of all alternative project delivery methods, especially with integrated project delivery (IPD). With IPD, the owner, designers, contractor, and major subs all agree to sign a single contract between all the parties and share the risks and rewards on the project. This has been rare in North Carolina up until recently, when some very sophisticated owners in North Carolina have procured large projects using IPD. Although many of the players are still learning the process “on the fly,” we should expect to see more of IPD, especially as it becomes more familiar to owners and construction firms in Florida.

At Carolina Consultants, we are experienced in IPD methods as well as the other alternative project delivery methods. If you are a contractor we can help you with the new delivery technologies, such as Lean Planning and 4D Scheduling. If you’re an owner, we can help you to choose method that will work best for your project and see it through to the end. Contact us today for a free consultation.